Introduction

> Solid Fuel Coal Fired Boiler

Capacity: 40kw-7000kw 100kg-2000kg/h

Fully automatic coal steam/hot water boiler, kind of fixed grate type coal feeder boiler. It adopts water-tubes & fire tubes design for heat transferring. Thermal efficiency is about 85%.

> Boiler Advantages

1. Complete combustion with high thermal efficiency

Adopt semi-gasification combustion way, negative pressure combustion inner furnace, reasonable proportion of air distribution to reach compelte combusition, make its higher efficiency, and the emission is free of visible smoke and dust.

2. High efficiency

Large heating area, high thermal efficiency, wide range of coal types, strong combustion firepower, good heating effect, 13% more energy-saving than similar products in the industry.

3. One-touch operation, safe and convenient

Equipped with a microcomputer LCD control system, one-button start, press the key, it will enter a fully automatic operation state, safe and convenient.

4. Multiple protection safety guarantee

The product is equipped with high-quality pressure controller, safety valve, multiple protections such as overpressure, low water level and overheating protection to ensure product quality and safe use.

5. Together with cyclone dust collector, reduce emission concentration.

Environmental friendly, obey to local emission standard strictly.

6. Modular delivery, it is installed before delivery.

The coal boiler is installed before delivery. In site, only needs to be connected to the power supply, water inlet/outlet pipe and sewage pipe, help saving the installation cost and installation materials.

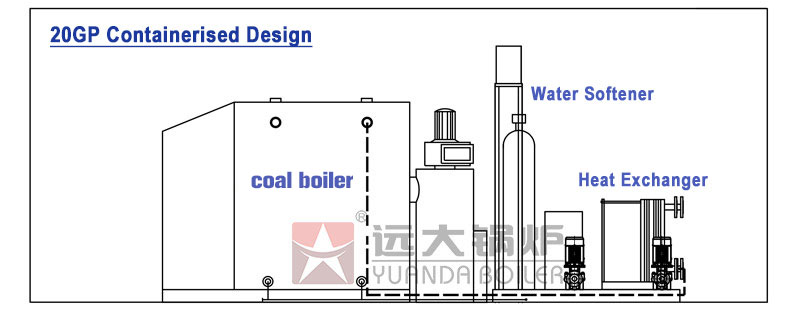

> Customized Mobile Boiler

Portable type coal hot water boiler in container. (Heating system customized for any customer needs.)

1. Coal hot water boiler in a container, which is specially prepared for buildings - where there is no enough space for the boiler and fuel room.

2. Containerised mobile type coal boiler plants are fully operational coal heating systems built inside a custom made container with fire-resistant walls. They include a silo, a boiler, the automation and all the electrical works and plumbing already made in the factory. They are easy to install and easy to relocate.

> Related: Biomass/Coal Fired Boiler

Industrial coal boiler, wood boiler, biomass boiler, solid waste boiler

Boiler Features

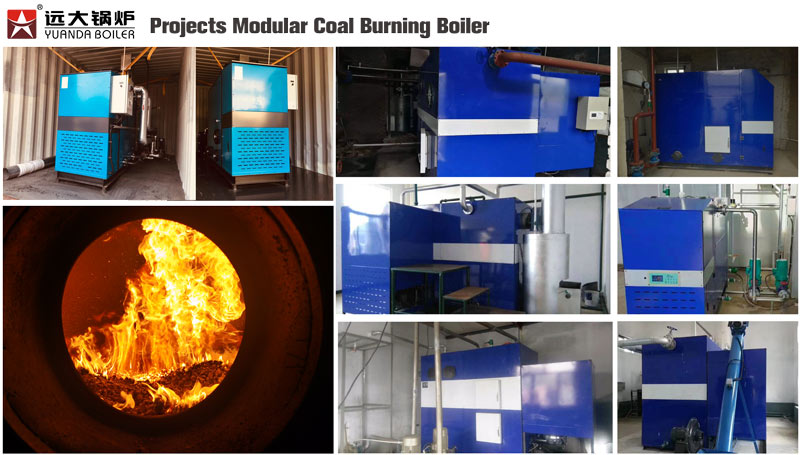

Combustion Show

Automatic ignition & combustion stage. Show biomass pellets combustion, burning at high efficiency, strong power.

Modular Integration

Compact structure and light weight; One-button start up/off; Automatic control system; Available to move everywhere.

Water Treatment Device

Hard water is softened by removing the hardness minerals in the water through a process called ion exchange.

Controller Cabinet

Support customized service on control system, pls send your requirements.Technical Parameter

| Model | CLHS-0.084 | CLHS-0.12 | CLHS-0.175 | CLHS-0.24 | CLHS-0.35 | CLHS-0.54 | CLHS-0.72 | CLHS-1.08 | CLHS-1.44 | CLHS-1.8 | CLHS-2.1 | CLHS-2.8 | CLHS-4.2 | |

| Working Pressure | Atmospheric Type | |||||||||||||

| Thermal Efficiency | 80%-85% | |||||||||||||

| Rated out put | ×10⁴kcal/h | 7 | 10 | 15 | 20 | 30 | 45 | 60 | 90 | 120 | 150 | 180 | 240 | 360 |

| Heating area | ㎡ | 700 | 1000 | 1500 | 2000 | 3000 | 4500 | 6000 | 9000 | 12000 | 15000 | 18000 | 24000 | 36000 |

| Rated Voltage | V | 220v 380v (Customized) | ||||||||||||

| Induced Fan Power | kw | 0.75 | 1.5 | 2.2 | 3 | 5 | 7.5 | 11 | 18 | 22 | ||||

| Chimney Diameter | mm | 160 | 165 | 220 | 220 | 273 | 325 | 325 | 375 | 375 | 426 | 426 | 500 | 500 |

| Circulating Water Volume | m³/h | 2.8 | 4 | 6 | 8 | 12 | 18 | 24 | 36 | 48 | 60 | 72 | 96 | 114 |

| Water Inlet and Outlet Diameter | 1.5” | 2” | 3” | 4” | 5” | |||||||||

| Dust Collector | 400*1170 | 460*1200 | 480*1600 | 700*1800 | 800*2100 | 900*2100 | 1000*2300 | |||||||

| Fuel Consumption | kg/h | 13 | 18 | 28 | 36 | 55 | 80 | 108 | 161 | 215 | 268 | 322 | 430 | 650 |

| Boiler Size | L (mm) | 1900 | 1960 | 2100 | 2200 | 2300 | 2650 | 2850 | 3000 | 3300 | 3500 | 3650 | 4100 | 5100 |

| W (mm) | 750 | 800 | 800 | 900 | 1000 | 1100 | 1200 | 1350 | 1500 | 1550 | 1650 | 1890 | 2200 | |

| H (mm) | 1300 | 1460 | 1550 | 1800 | 2000 | 2100 | 2200 | 2250 | 2300 | 2450 | 2550 | 2650 | 2880 | |

| Shipping Weight | kg | 650 | 800 | 900 | 1200 | 1600 | 2200 | 2800 | 3500 | 4000 | 4500 | 5500 | 5800 | 6200 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | ||||||||||||||

Supply Boiler & Accessories

About us

Yuanda Products

steam boiler, steam generator, hot water boiler, thermal oil heater boiler, hot air furnace, waste incinerator.

Various Structure

vertical, horizontal, fire tube boiler, water tube boiler, coils heater boiler, water membrane wall structure, sing drum, double drum...

Application

widely in all industries productions heating drying process, building central heating system, electricity generation.

About us

Yuanda Boiler Company established in 1956, qualified by ISO, CE, ASME, EAC, DOSH, and CRN, ensuring safety, reliability, and quality.

Yuanda Service

We provide tailored boiler solutions. Our team shares catalogues, evaluates your working conditions, and recommends the most suitable model for your needs.

✅ Design & Manufacture

Customized boiler design and system diagram. High-standard manufacturing with strict quality control, certified by ISO, CE, ASME, and more.

✅ Boiler Foundation Preparation

Complete foundation drawings, piping layout, and operation documents to ensure smooth installation and operation.

✅ Engineer Service

On-site guidance for installation and commissioning. Professional training for operators to ensure safe and efficient boiler operation.

✅ After-Sales Support

24/7 online technical assistance, spare parts supply, and regular maintenance services — ensuring long-term reliable performance.

Contact Yuanda

YUADNA PRODUCTS

HOT PRODUCTS

Send Inquiry

Steam Capacity:

Steam Capacity: Heat Capacity:

Heat Capacity: Fuel:

Fuel: Usage:

Usage: