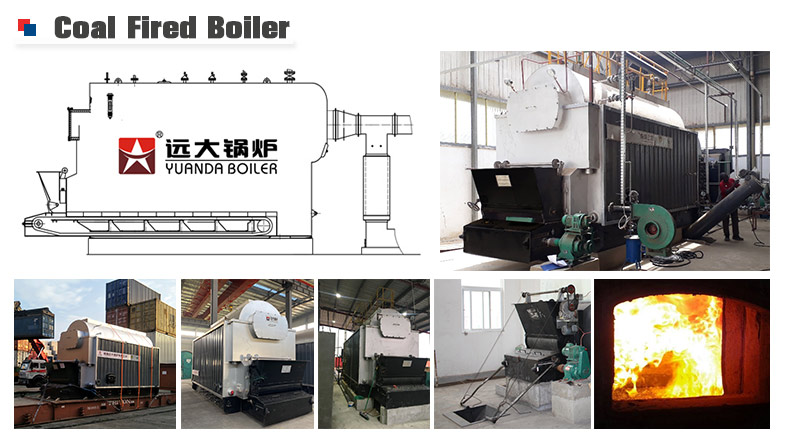

Introduction

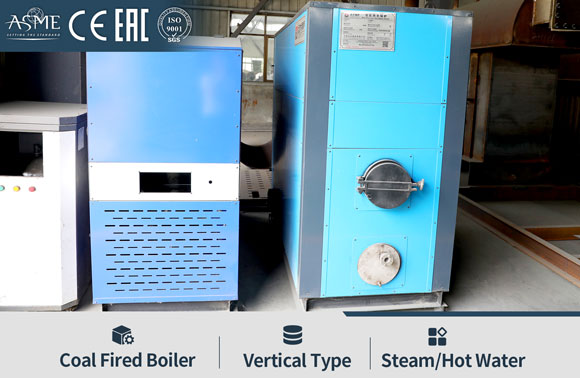

Coal Hot Water Boiler

Certified by ASME, CE, ISO, EAC, DOSH, TUV, BUV, ensuring high quality and compliance with international standards.

Most Popular model: DZL coal heating boiler automatic chain grate boiler

DZL automatic coal boiler, with chain grate combustion device, adopt automatic coal feeding system, inner fire-tube & water-tube structure, wing-shape flue and flue gas three pass design, higher thermal efficiency than traditional manual coal boiler.

Themal Capaity in 0.7MW-28MW Automatic Coal Heating Boiler

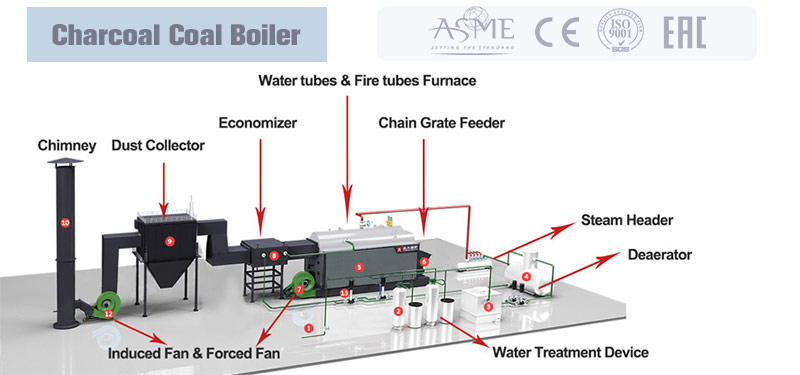

Coal Fired Boiler System

Complete boiler system need some other accessories for help boiler work successfully. Introduce some important accessories as following:

1. Water softener ②, Remove Mg+,Ca+ in the water and improve water quality, prevent hurt to boiler tube, entend the boiler using life time.

2. Economizer ⑧, use exhaust gas to heat inlet-water then reduce exhaust gas temperature, which improve boiler efficiency.

3. Dust collector ⑨, bag filter, Remove the dust and ash in exhaust gas to protect environment and reduce pollutions.

4. Forced fan & Induced fan ⑦, Blow clean air into the boiler and promote exhausted gas out, ensure the air circulation of the whole system.

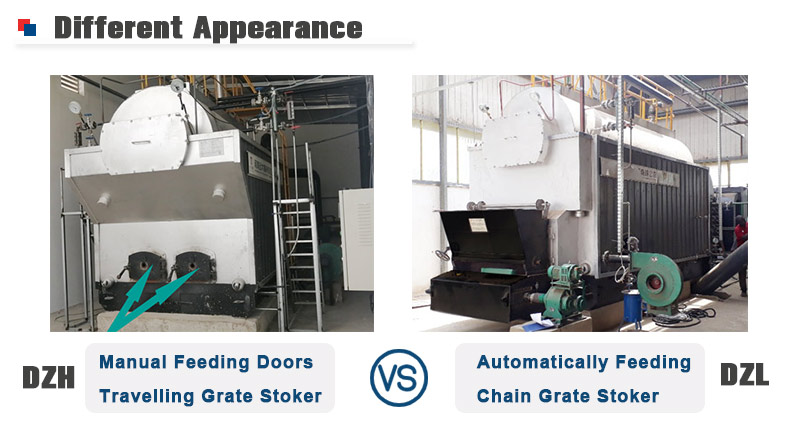

DZH Manual Feeding Coal Boiler

DZH series is kind of manual coal feeding boiler, need labor works to feeding coal into stoker.

Product: Small Coal Fired Boiler

Small coal hot water boiler in 41kw-1400kw.

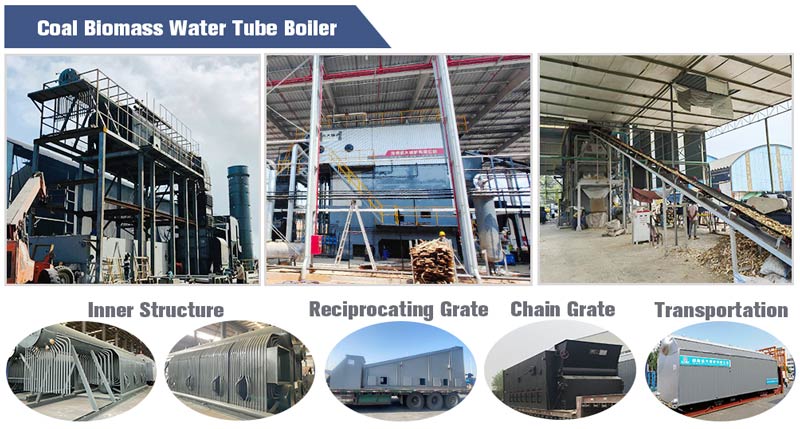

Product: Water Tube Coal Boiler

SZL Series water tube coal boiler 2ton-50ton/hour.

DZL Boiler Features

Chain grate

Auto-feeding type burning system, avoid problem of air leakage, fuel leakage and uneven ventilation. Easier operation compared to traditional grate.

Water Softener

A complete water treatment system is included to remove hardness and prevent scale formation, protecting the boiler and improving efficiency.

Security guaranteed & Automation

Multiple safety and monitoring devices — pressure gauge, water level gauge, temperature sensor, and automatic safety protection system — ensure safe and reliable operation.

Economizer for Energy Saving

Equipped with a high-efficiency economizer to utilize waste heat from flue gas, reduce fuel consumption, and improve overall thermal efficiency.Technical Parameter

| DZ Series Hot Water Boiler Technical Parameter Table | |||||||||

| Model | Rated capacity(MW) | Rated pressure (Mpa) | Rated output temperature(℃) | Rated return water temperature(℃) | Thermal efficiency(%) | Fuel comsumption(Kg/h) | Exhaust temperation(℃) | max transportation weigh(t) | |

| DZL0.7 | 0.7 | 0.7 | 95/115 | 70 | >80 | 181 | <130 | 10 | |

| DZL1.4 | 1.4 | 1.0 | 95/115 | 70 | >80 | 370 | <130 | 22.5 | |

| DZL2.8 | 2.8 | 1.0 | 95/115 | 70 | >80 | 727 | <130 | 26.5 | |

| DZL4.2 | 4.2 | 1.0 | 95/115 | 70 | >80 | 1080 | <130 | 35.7 | |

| DZL5.6 | 5.6 | 1.0 | 95/115 | 70 | >80 | 1390 | <130 | 40.2 | |

| DZL7.0 | 7.0 | 1.0 | 95/115 | 70 | >80 | 1726 | <130 | 25.6 | |

| DZL10.5 | 10.5 | 1.0 | 95/115 | 70 | >80 | 2530 | <130 | 18 | |

| DZL14 | 14 | 1.0 | 95/115 | 70 | >80 | 3390 | <130 | 19.9 | |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||

Supply Boiler & Accessories

About us

Yuanda Products

steam boiler, steam generator, hot water boiler, thermal oil heater boiler, hot air furnace, waste incinerator.

Various Structure

vertical, horizontal, fire tube boiler, water tube boiler, coils heater boiler, water membrane wall structure, sing drum, double drum...

Application

widely in all industries productions heating drying process, building central heating system, electricity generation.

About us

Yuanda Boiler Company established in 1956, qualified by ISO, CE, ASME, EAC, DOSH, and CRN, ensuring safety, reliability, and quality.

Yuanda Service

We provide tailored boiler solutions. Our team shares catalogues, evaluates your working conditions, and recommends the most suitable model for your needs.

✅ Design & Manufacture

Customized boiler design and system diagram. High-standard manufacturing with strict quality control, certified by ISO, CE, ASME, and more.

✅ Boiler Foundation Preparation

Complete foundation drawings, piping layout, and operation documents to ensure smooth installation and operation.

✅ Engineer Service

On-site guidance for installation and commissioning. Professional training for operators to ensure safe and efficient boiler operation.

✅ After-Sales Support

24/7 online technical assistance, spare parts supply, and regular maintenance services — ensuring long-term reliable performance.

Contact Yuanda

YUADNA PRODUCTS

HOT PRODUCTS

Send Inquiry

Heat Capacity:

Heat Capacity: Fuel:

Fuel: Usage:

Usage: Certificates:

Certificates: