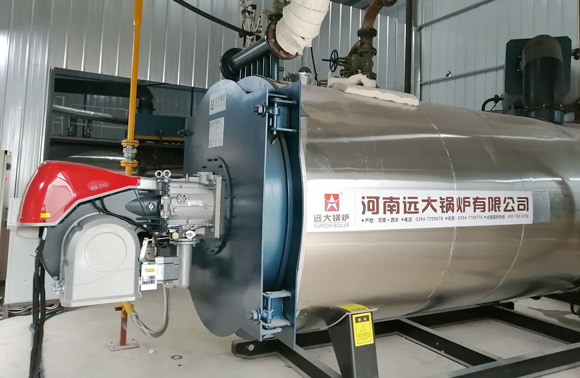

Introduction

YLW Chain Grate Thermal Oil Boiler | use coal, wood biomass

Horizontal type thermal oil boiler, use chain grate for automatic feeding, high efficiency, environmental-friendly.

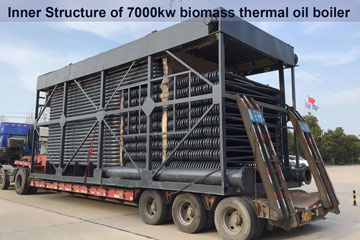

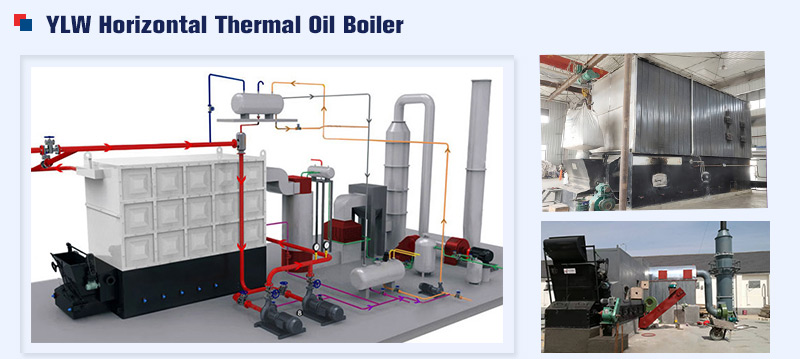

Introduction: Horizontal type thermal oil heater boiler, it has a square coil tube horizontal structure, adopt chain grate mechanical feeding, equipped with a drum and induced draft fan for mechanical ventilation, and equipped with a slag machine to achieve mechanical slag.

How it work: In thermal oil boiler, thermal oil as heat medium, using the circulating pump to force the liquid thermal oil circulation, then transportingthermal oil though pipes into customers' thermal equipment, do successful heat exchange. Then, thermal oil return back the thermal oil boiler.

Whole System including thermal oil heater boiler proper, stoker, control cabinet, oil expansion tank, oil storage tank, oil circulating pumps, ID fan, forced fan, economizer, chimney, pipes, valves, gauges, etc.

Energy efficient

1. Close packed disc tube heating surface, heating surface layout adequacy, multi-backhaul heat exchanger.

2. Furnace size match with burning flame, radiation heat transfer efficiency.

3. Positive pressure combustin, so that combustion efficiency is greatly improved.

4. Boiler quality insulation materials and special construction technology, less heat loss, ther exhaust gas temperature is low, the high thermal efficiency of ther boiler.

5. By fully rational surface layout, boiler warming fast start.

Safe and reliable

1. Close-packed disc tube heating surface heating surface arrangement sufficient to reduce the tube sheet heat load, conducting oil safer to use.

2. The boiler operation monitor remote and nearly complete automatic control and monitoring instrumentation, safe, reliable, easy to operate

Easy to install

Boiler full assembled, compact structure, small footprint, is extremely easy to install and flexible, as long as the boiler is located based on.

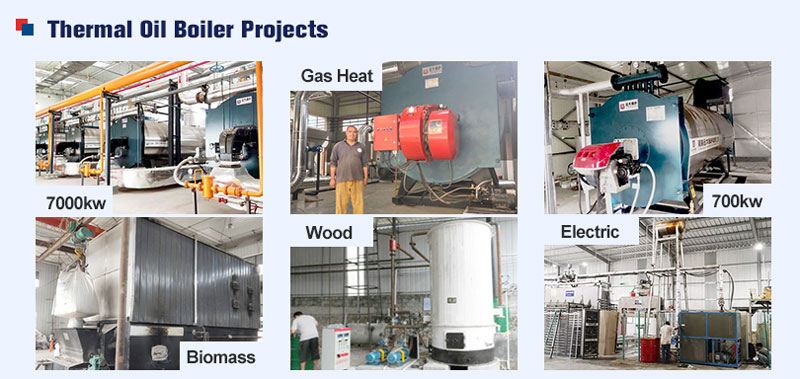

Application of thermal oil boiler

1. Fuel applicable: Electric, Gas, Lpg, Diesel, Heavy Oil, Coal, Wood, Biomass, Agro Waste.

2. Application industry: Cement industry, Chemical/petrochemical industry, Polymer industry, Textile industry, Leather industry, Oil industry, Glue industry, Food processing industry, Metal industry, Tyre industry, Bitumen & Tar processing industry, Paper mills industry, Wood industry, Soap Detergent industry, Pharmaceutical industry, Paint Varnish industry Packing Packaging industry, Glass industry, Industrial Laundries. etc.

Technical Parameter

| YLW Series Thermal Oil Boiler Technical Parameter | |||||||

| Model | Rated power(KW) | Rated pressure (Mpa) | Thermal oil temperature(℃) | Thermal efficiency(%) | Thermal oil circulation flow(m³/h) | Fuel comsumption(Kg/h) | max transportation weigh(t) |

| YLW-700 | 0.7 | 0.8/1.0 | 250-320 | >83 | 45.7 | 187 | 16.9 |

| YLW-1400 | 1.4 | 0.8/1.0 | 250-320 | >83 | 87.4 | 373 | 22 |

| YLW-2400 | 2.4 | 0.8/1.0 | 250-320 | >83 | 149.8 | 621.3 | 28.6 |

| YLW-2900 | 2.9 | 0.8/1.0 | 250-320 | >83 | 155 | 756 | 24.2 |

| YLW-4200 | 4.2 | 0.8/1.0 | 250-320 | >83 | 225 | 989.3 | 30 |

| YLW-5600 | 5.6 | 0.8/1.0 | 250-320 | >83 | 336 | 1196 | 33.6 |

| YLW-7000 | 7 | 0.8/1.0 | 250-320 | >83 | 383.5 | 1657.4 | 18.2 |

| YLW-8400 | 8.4 | 0.8/1.0 | 250-320 | >83 | 536.2 | 1926.2 | 24.3 |

| YLW-10500 | 10.5 | 0.8/1.0 | 250-320 | >83 | 686.6 | 2442.6 | 27.5 |

| YLW-14000 | 14 | 0.8/1.0 | 250-320 | >83 | 869.1 | 3230 | 31 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||

Our Supply Equipment List

Technical Design

Multi-loop coil design

Adopts square coil horizontal sturcture, chain grate automatic fuel feeding combustion device, increase heating surface and easier to operate.

Unique warehouse and auto feeding

The big speed bin design could control fuel transmit mass automatically according to the thermal energy, isolate flame and flue to prevent tempering

Countercurrent heat transfer process

After rediation heat transfer by rediation heating surface, it enters the convection heating surface for convection heat transfer.

Economizer & Dust collector device

Reuse waste heat in exhaust gas, energy saving devide (economizer); Remove the dust and ash, protect envrionment and reduce pollutionFAQ Thermal Oil Boiler

Question: How do thermal oil heaters work?

Answer: Thermal oil heaters circulate a heat-transfer fluid (thermal oil) through a closed system. The oil is heated in a furnace and then passed through a heat exchanger, where it transfers heat to the process or equipment. This system allows for efficient heat transfer at high temperatures without high pressure.

Question: What's thermal oil heating temperature ?

Answer: Mostly, heating system for Thermal Fluids, operate at very high temperatures up to 400°C or higher.

PRODUCT LIST

YOU MAY ALSO LIKE

Ask For Catalogue

Send Inquiry

Product capacity:

Product capacity: Working pressure:

Working pressure: Available fuel:

Available fuel: Available industries:

Available industries: