Introduction

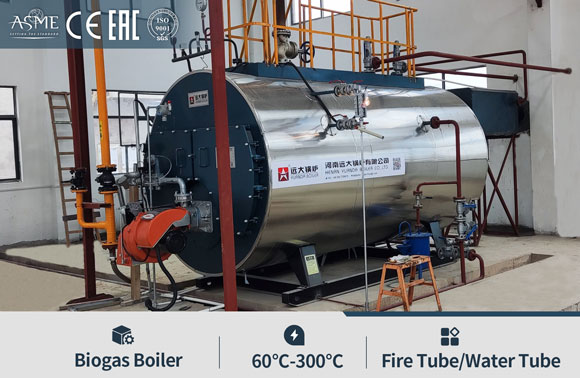

> Biogas Fired Boiler

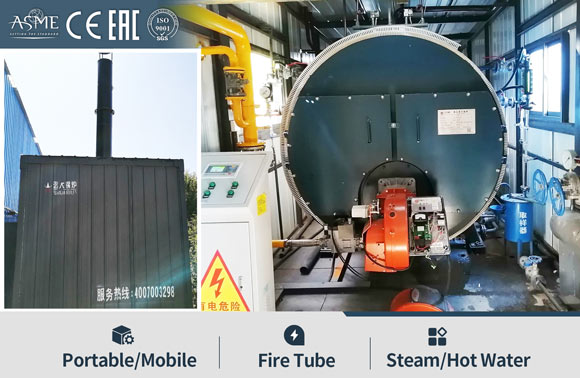

Yuanda Biogas Fire Tube Packaged Boiler

WNS Series Horizontal Type Wet Back Three Pass boiler, with higher-efficiency up 99% & energy-saving & fully automatic running. Importantly, it has a lower NOx emissions, environmental-friendly.

> Biogas Boiler Advantages

Biogas boiler is a type of boiler that utilizes biogas as its primary fuel source for heating purposes.

Biogas is considered as a renewable energy source, It can be burnt within the boiler to produce heat energy. Use biogas as a fuel for boiler can contribute to reducing greenhouse gas emissions.

✅Lower operating costs through renewable biogas utilization.

✅Significant reduction in greenhouse gas emissions.

✅Suitable for continuous industrial operation with low maintenance requirements.

✅Customizable capacity and pressure according to your request.

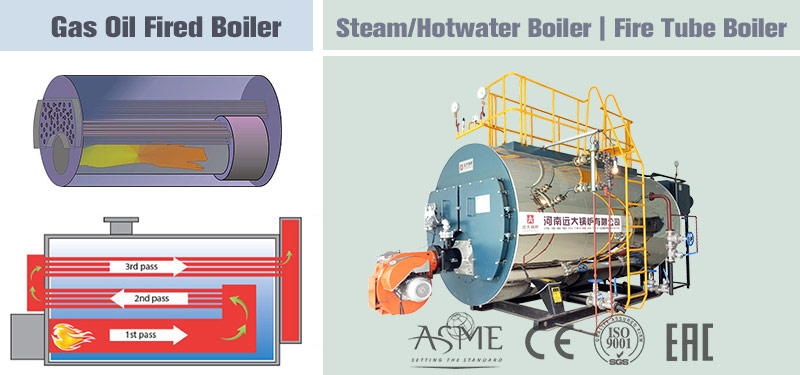

> Fire Tube Boiler Structure

WNS boiler body with characteristics of "fan-shape three pass boiler" "wet-back boiler" "corrugated-furnace" "smoke change chamber" "spirally tube", greatly improve thermal efficiency up to 99%.

> Hot Products

Yuanda Products Qualifed by ISO CE ASME, Global Sale Service Cover 132 Countries.

Boiler Features

100% Safety

We make the ultrasonic flaw detection and water pressure test for body body and pressurized part. Boiler equipped with double gauges & safety valves

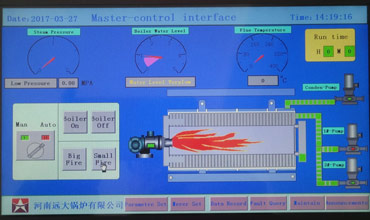

High Automation Boiler

Intelligient control panel of boiler, it controls the size of the flame of the burner, water level, pressure, temperature and other signals inside the boiler

Energy-Saving Boiler

Three pass boiler, three pass can extend the flue gas distance, enhance heat transfer and increase thermal efficiency. Full heat insulation condenser design

Environmental Friendly

WNS series boiler, it could satisfy all countries' environment NOx emission limit standard. We are on the way to green environment protectionTechnical Parameter

| Model | Rated capacity(t/h) | Rated pressure (Mpa) | Rated temperature(℃) | feed temperature(℃) | Thermal efficiency(%) | Exhaust temperation(℃) | Fuel comsumption | max transportation weigh(t) | |

| light diesel oil(kg/h) | natural gas(Nm³/h) | ||||||||

| WNS0.5 | 0.5 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >98 | 60-75 | 32.5 | 35.7 | 3.5 |

| WNS1 | 1 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >98 | 60-75 | 64.5 | 70.1 | 5.5 |

| WNS2 | 2 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >98 | 60-75 | 129.3 | 140.3 | 8 |

| WNS3 | 3 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >98 | 60-75 | 192.9 | 212.1 | 10.7 |

| WNS4 | 4 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >98 | 60-75 | 258.2 | 283.4 | 11.6 |

| WNS6 | 6 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >98 | 60-75 | 388.6 | 424.2 | 17.5 |

| WNS8 | 8 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >98 | 60-75 | 514.6 | 566.3 | 22.5 |

| WNS10 | 10 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >98 | 60-75 | 641.7 | 707.8 | 26.8 |

| WNS15 | 15 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >98 | 60-75 | 960.1 | 1061.7 | 35.2 |

| WNS20 | 20 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >98 | 60-75 | 1276.2 | 1415.8 | 45.5 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||

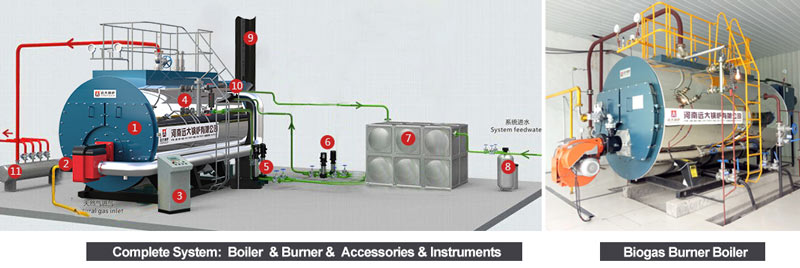

Supply Boiler & Accessories

Boiler Consumption

Boiler Running Cost

For example, 1ton biogas boiler comsumes 120–140 Nm³/h of biogas, depending on the methane concentration.

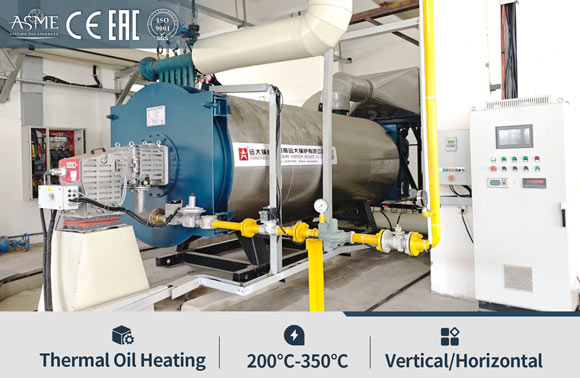

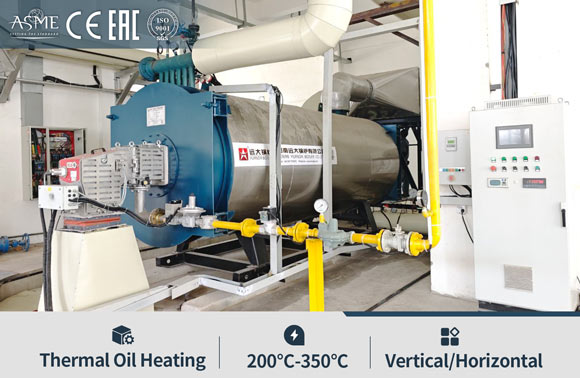

Various Structure

vertical, horizontal, fire tube boiler, water tube boiler, coils heater boiler, water membrane wall structure, sing drum, double drum...

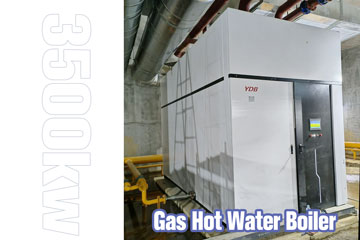

Yuanda Products

steam boiler, steam generator, hot water boiler, thermal oil heater boiler, hot air furnace, waste incinerator.

About us

Yuanda Boiler Company established in 1956, qualified by ISO, CE, ASME, EAC, DOSH, and CRN, ensuring safety, reliability, and quality.

Yuanda Service

We provide tailored boiler solutions. Our team shares catalogues, evaluates your working conditions, and recommends the most suitable model for your needs.

✅ Design & Manufacture

Customized boiler design and system diagram. High-standard manufacturing with strict quality control, certified by ISO, CE, ASME, and more.

✅ Boiler Foundation Preparation

Complete foundation drawings, piping layout, and operation documents to ensure smooth installation and operation.

✅ Engineer Service

On-site guidance for installation and commissioning. Professional training for operators to ensure safe and efficient boiler operation.

✅ After-Sales Support

24/7 online technical assistance, spare parts supply, and regular maintenance services — ensuring long-term reliable performance.

Contact Yuanda

YUADNA PRODUCTS

HOT PRODUCTS

Send Inquiry

Capacity:

Capacity: Pressure:

Pressure: Types:

Types: Structure:

Structure: