Introduction

Product: Oil Gas Fired Hot Water Boiler

1. Vertical diesel/gas lpg boiler, small hot water boiler in 60kw-1400kw.

2. Horizontal oil-fired gas-fired boiler, fire tube boiler, three pass boiler, high thermal efficiency & energy saving boiler. Capacity in 350kw-14000kw.

Capacity: 100kw 200kw 300kw 500kw 700kw 1000kw 1400kw 2100kw 2800kw 3500kw 4200kw 5600kw 7000kw 14000kw

Capacity: 100,000kcal to 24,000,000kcal

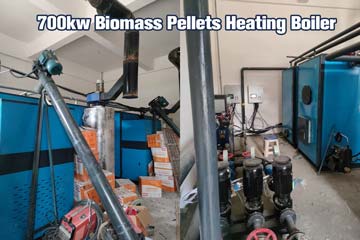

Product: Solid Fuel Coal Biomass Boiler

(Options: coal, wood, biomass, bagasse, rice husk, palm kernel shells, agro waste)

1. Small coal/wood biomass fired boiler, widely for small industries processing, hotel/school hot water system, commercial laundry...

2. Industrial coal wood biomass fired boiler 1ton-50ton, used for factory production heat & electricity generation, bulidings central heating...

Capacity: 40kw 56kw 88kw 100kw 150kw 180kw 250kw 350kw 500kw 700kw 1400kw 2800kw 4200kw 5600kw 7000kw to 28000kw

Capacity: 50,000kcal to 24,000,000kcal

Customized Coal-fired Biomass-fired Boiler Solutions For You

More Products

1. Mobile boiler, skid mounted boiler

2. Hot air generator furnace

3. Exhaust gas steam generator boiler

4. Thermal oil steam generator

If have any interest, please contact by email or whatsapp directly.

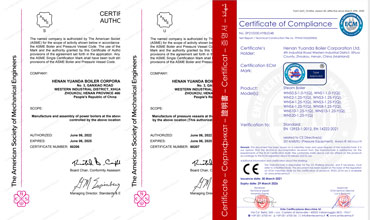

Boiler Manufacturing and Inspection

Certified Manufacturing Standards

All boilers are designed and manufactured under ASME, CE, and ISO certifications, ensuring full compliance with international pressure vessel and safety standards.

Strict Quality Control System

From raw material selection to welding, assembly, and hydrostatic testing, every process is strictly monitored. Each boiler is 100% inspected and tested before delivery.

Factory Audit and Third-Party Inspection Support

Welcome customers and authorized agencies to conduct factory inspections (audit) and witness testing. Third-party inspections such as SGS, BV, or TUV.

Experienced Technical Team

With 69 Years boiler manufacturing experience since 1956, our skilled engineers and technicians ensure each unit meets the highest performance and safety standards.Technical Parameter

| WNS Series Fire Tube Hot Water Boiler Technical Parameter | |||||||||

| Model | Rated power(MW) | Rated pressure (Mpa) | Rated output temperature(℃) | Rated return water temperature(℃) | Thermal efficiency(%) | Exhaust temperation(℃) | Fuel comsumption | max transportation weigh(t) | |

| light diesel oil(kg/h) | natural gas(Nm³/h) | ||||||||

| WNS0.35 | 0.35 | 0.7/1.0/1.25 | 95/115/130 | 70 | >97 | 60-75 | 31.6 | 36.6 | 2.65 |

| WNS0.7 | 0.7 | 0.7/1.0/1.25 | 95/115/130 | 70 | >97 | 60-75 | 60.4 | 69.3 | 4.66 |

| WNS1.4 | 1.4 | 0.7/1.0/1.25 | 95/115/130 | 70 | >97 | 60-75 | 122.8 | 146.1 | 6.53 |

| WNS2.1 | 2.1 | 0.7/1.0/1.25 | 95/115/130 | 70 | >97 | 60-75 | 192.3 | 227.1 | 7.3 |

| WNS2.8 | 2.8 | 0.7/1.0/1.25 | 95/115/130 | 70 | >97 | 60-75 | 246.1 | 286.5 | 8.1 |

| WNS4.2 | 4.2 | 0.7/1.0/1.25 | 95/115/130 | 70 | >97 | 60-75 | 367.1 | 412.6 | 15.1 |

| WNS5.6 | 5.6 | 0.7/1.0/1.25/1.6 | 95/115/130 | 70 | >97 | 60-75 | 490.2 | 543.7 | 18.2 |

| WNS7.0 | 7.0 | 0.7/1.0/1.25/1.6 | 95/115/130 | 70 | >97 | 60-75 | 593.6 | 660.7 | 25.6 |

| WNS10.5 | 10.5 | 0.7/1.0/1.25/1.6 | 95/115/130 | 70 | >97 | 60-75 | 936.5 | 998.8 | 29.1 |

| WNS14.0 | 14.0 | 0.7/1.0/1.25/1.6 | 95/115/130 | 70 | >97 | 60-75 | 1200.8 | 1330.7 | 47.8 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||

Boiler Accessories

About us

Yuanda Products

steam boiler, steam generator, hot water boiler, thermal oil heater boiler, hot air furnace, waste incinerator.

Various Structure

vertical, horizontal, fire tube boiler, water tube boiler, coils heater boiler, water membrane wall structure, sing drum, double drum...

Application

widely in all industries productions heating drying process, building central heating system, electricity generation.

About us

Yuanda Boiler Company established in 1956, qualified by ISO, CE, ASME, EAC, DOSH, and CRN, ensuring safety, reliability, and quality.

Yuanda Service

We provide tailored boiler solutions. Our team shares catalogues, evaluates your working conditions, and recommends the most suitable model for your needs.

✅ Design & Manufacture

Customized boiler design and system diagram. High-standard manufacturing with strict quality control, certified by ISO, CE, ASME, and more.

✅ Boiler Foundation Preparation

Complete foundation drawings, piping layout, and operation documents to ensure smooth installation and operation.

✅ Engineer Service

On-site guidance for installation and commissioning. Professional training for operators to ensure safe and efficient boiler operation.

✅ After-Sales Support

24/7 online technical assistance, spare parts supply, and regular maintenance services — ensuring long-term reliable performance.

Contact Yuanda

YUADNA PRODUCTS

HOT PRODUCTS

Send Inquiry

Heat Capacity:

Heat Capacity: Capacity:

Capacity: Fuel:

Fuel: Use:

Use: