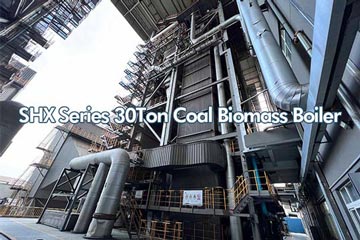

Introduction

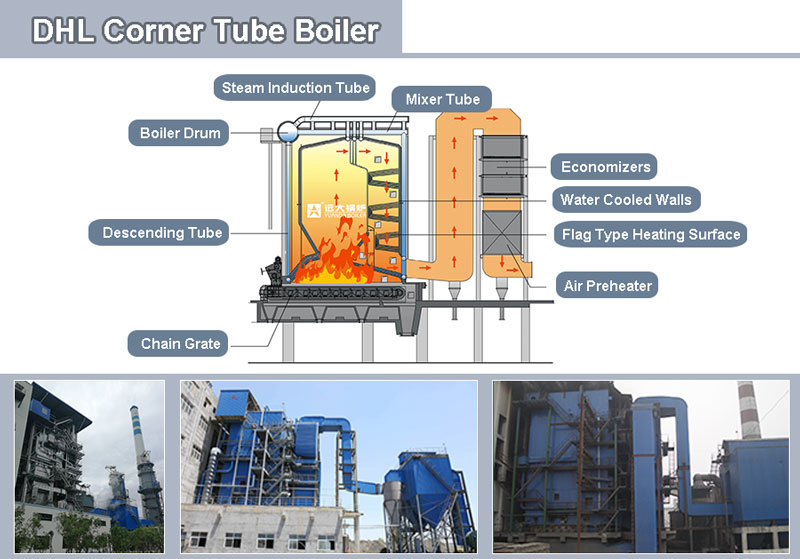

DHL Corner Tube Boiler

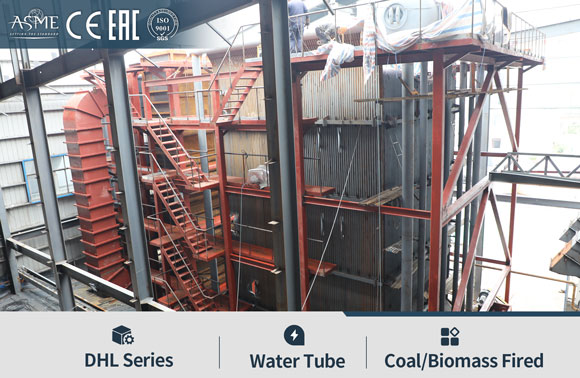

Structure: self-supporting structure water tube boiler

Available fuel: coal, wood, biomass, bagasse, ricehusk, palm kernel shells, etc.

Combustion technology: chain grate, reciprocating/step grate

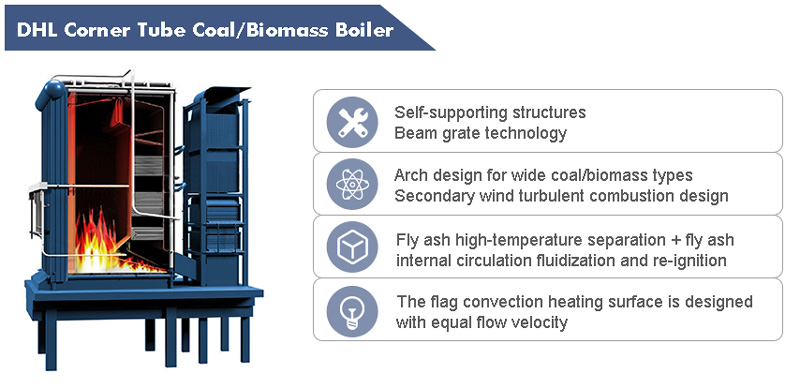

Design Features and Advantages

1. High Thermal Efficiency

Optimized furnace geometry, large cross-section design, secondary air distribution, and a refined back-arch structure ensure complete combustion, effectively reducing fly ash and slag losses.

2. Low Investment & Operating Cost

Compact structure with low steel consumption and light overall weight reduces civil construction costs. Modular fabrication minimizes on-site installation workload and shortens the installation cycle.

3. Low Emissions & Environmental Compliance

The multi-flue secondary dust separation design significantly lowers initial dust concentration, helping the boiler meet strict emission standards.

4. Safe, Stable & High-Quality Steam Output

The corner tube skeleton-free structure provides excellent seismic resistance and reliable natural water circulation. Pre-separation of steam and water ensures fast circulation startup and high steam purity.

Typical Configuration for Coal/Biomass Combustion

DHL corner tube boiler for these fuels is typically a packaged water tube boiler with the following components:

1. Furnace

The large, water-cooled chamber lined with the corner tube walls.

2. Grate System

Usually, a chain grate or reciprocating grate stoker is installed at the bottom of the furnace. This mechanical grate continuously feeds fuel from the front and moves ash out the back, allowing for stable and automated combustion.

3. Combustion Air System

Air is supplied as Primary Air (under the grate, for fuel bed combustion) and Secondary Air (above the grate, for burning volatile gases and creating turbulence for complete combustion).

4. Convection Section

Located after the furnace, this area contains banks of tubes where hotter flue gases transfer heat to the water/steam, further increasing efficiency.

5. Fuel Feeding System

Consists of a hopper and a conveyor that automatically feeds coal or biomass onto the moving grate.

6. Dust Collection & Ash Handling

Multistage dust collectors (Cyclones, Bag Filters) are used. Separate systems often handle fly ash (from the convection pass) and bottom ash (from the grate).

Technical Parameter

| DHL Series Corner Tube Steam Boiler Parameters | |||||

| Model | Capacity (ton/h) | Working Pressure | Steam Temperature | Input Water Temp. | Factory mode |

| DHL20 | 20 | 1.25Mpa-4.5Mpa | 194℃-450℃ |

105℃-112℃ |

Field Assembly |

| DHL25 | 25 | ||||

| DHL30 | 30 | ||||

| DHL40 | 40 | ||||

| DHL50 | 50 | ||||

| DHL60 | 60 | ||||

| DHL65 | 65 | ||||

| DHL80 | 80 | ||||

Auxiliary System

About us

Yuanda Products

steam boiler, steam generator, hot water boiler, thermal oil heater boiler, hot air furnace, waste incinerator.

Various Structure

vertical, horizontal, fire tube boiler, water tube boiler, coils heater boiler, water membrane wall structure, sing drum, double drum...

Application

widely in all industries productions heating drying process, building central heating system, electricity generation.

About us

Yuanda Boiler Company established in 1956, qualified by ISO, CE, ASME, EAC, DOSH, and CRN, ensuring safety, reliability, and quality.

Yuanda Service

We provide tailored boiler solutions. Our team shares catalogues, evaluates your working conditions, and recommends the most suitable model for your needs.

✅ Design & Manufacture

Customized boiler design and system diagram. High-standard manufacturing with strict quality control, certified by ISO, CE, ASME, and more.

✅ Boiler Foundation Preparation

Complete foundation drawings, piping layout, and operation documents to ensure smooth installation and operation.

✅ Engineer Service

On-site guidance for installation and commissioning. Professional training for operators to ensure safe and efficient boiler operation.

✅ After-Sales Support

24/7 online technical assistance, spare parts supply, and regular maintenance services — ensuring long-term reliable performance.

Contact Yuanda

YUADNA PRODUCTS

HOT PRODUCTS

Send Inquiry

Capacity:

Capacity: Pressure:

Pressure: Fuel:

Fuel: Features:

Features: