Introduction

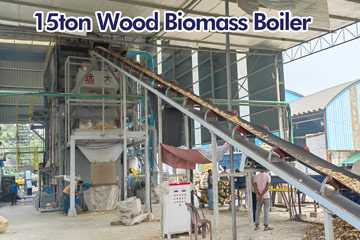

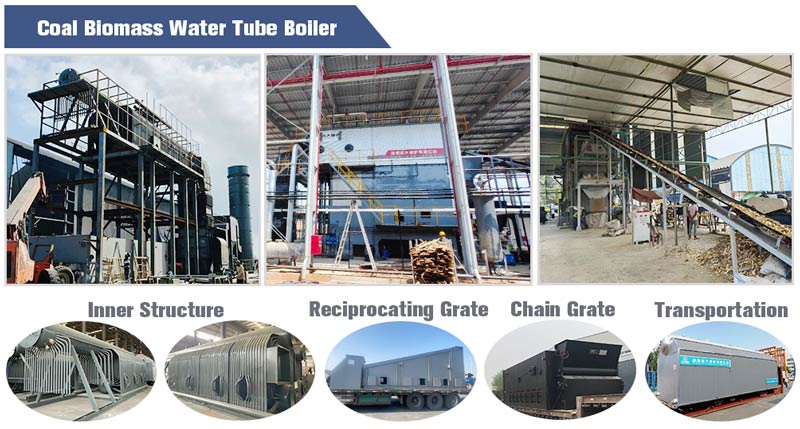

Industrial Solid Fuel Boiler

Fuel: coal, biomass, wood, sawdust, husk, pellets, charcoal, palm shells/fibre, coconut shell, bagasse, cashewnut shell, waste cloth...

Combustion Stoker Types: chain grate, travelling grate, vibrating grate, fixed grate, reciprocating grate, stationary grate, dumping grate.

Choose the suitable grate boiler

1. we need confirm "what's the fuel to burning".

2. we will make a fuel burning analysis, according to different fuel heat value and burning characteristics, we will advise you best-suitable grate combustion device for you.

Remark: Only when you choose the best-suitable grate device, the boiler could work efficiently, work for longer time stably,

Combustion Equipment-Grate

Chain grate

Auto-feeding type burning system, avoid the problem of air leakage, fuel leakage and uneven ventilation, and easy operation, have lots of advantages compared to traditional grate.

Reciprocating grate

Suitable for burning kinds of solid waste.include biomass, wood, bark, corn stover, agricultural fuels, walnut shells, peanut shells, wood pellets and other fuels with heat content.

Dumping grate

Suitable for Agro biomass waste burning. Made of optimum quality material our dumping products are embedded with all quality features.

Fixed grate

Fixed grate, is a very simple and effective system, and it is widespread in certain applications due to its reliability and robustness.Technical Parameter

| DZ Series Steam Boiler Technical Parameter Table | |||||||||

| Model | Rated capacity(t/h) | Rated pressure (Mpa) | Rated steam temperature(℃) | feed temperature(℃) | Thermal efficiency(%) | Boiler water volume(m³) | Exhaust temperation(℃) | Fuel comsumption(Kg/h) | max transportation weigh(t) |

| DZH1 | 1 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 3.15 | 127.25 | 192.32 | 9 |

| DZL1 | 1 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 3.15 | 113.34 | 190.42 | 13.5 |

| DZH2 | 2 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 4.75 | 126.41 | 386.47 | 15 |

| DZL2 | 2 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 4.77 | 106.34 | 393.77 | 22 |

| DZH4 | 4 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 7.7 | 137.25 | 782.29 | 18.5 |

| DZL4 | 4 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 8.2 | 124.49 | 756.89 | 27.6 |

| DZH6 | 6 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 7.4 | 146.83 | 1169.57 | 25 |

| DZL6 | 6 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 8.1 | 137.29 | 1148.68 | 35 |

| DZL8 | 8 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 9.6 | 141.06 | 1602.44 | 38 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||

Supply Boiler & Accessories

About us

Yuanda Products

steam boiler, steam generator, hot water boiler, thermal oil heater boiler, hot air furnace, waste incinerator.

Various Structure

vertical, horizontal, fire tube boiler, water tube boiler, coils heater boiler, water membrane wall structure, sing drum, double drum...

Application

widely in all industries productions heating drying process, building central heating system, electricity generation.

About us

Yuanda Boiler Company established in 1956, qualified by ISO, CE, ASME, EAC, DOSH, and CRN, ensuring safety, reliability, and quality.

Contact Yuanda

YUADNA PRODUCTS

HOT PRODUCTS

Send Inquiry

Capacity:

Capacity: Pressure:

Pressure: Fuel:

Fuel: Use:

Use: