Introduction

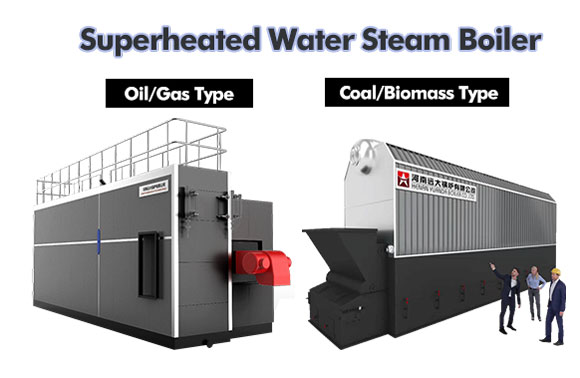

> Superheated Water Steam Boiler

Water Tube Boiler | Double Drums Water Membrane Wall Boiler | Fuel: Gas Diesel Heavy Oil / Coal Wood Biomass

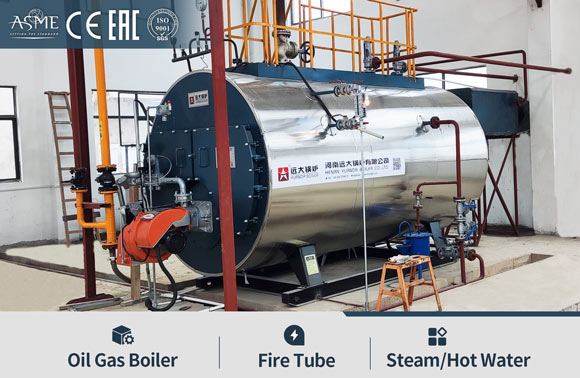

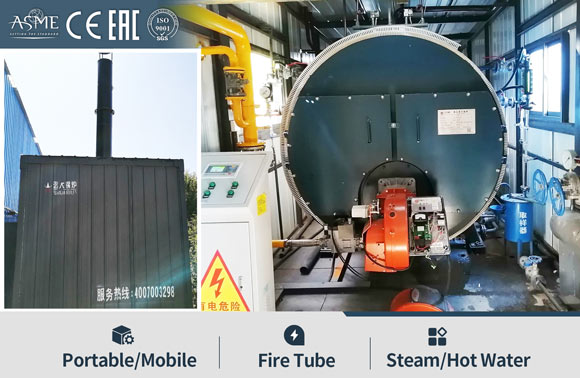

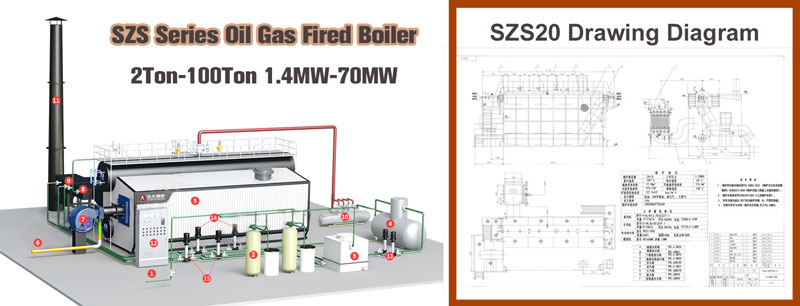

> Oil Gas Type Superheated Boiler

※ SZS Water Tube Superheated Boiler, Use gas, diesel, heavy oil, lpg, dual fuel. Capacity in 2ton-100ton.

※ SZS gas & oil water tube boiler is arranged as drum longitudinal type “D” shape, it’s quickly assembled boiler with water tube, has the characteristics of high steam quality, sufficient output, high thermal efficiency, etc.

※ The structure of furnace water cooling wall and convection gas pass is membrane wall, have good sealability, and effectively reduce refractory brick quantity and maintenance workload.

※ The layout of economizer at boiler tail could effectively reduces exhaust gas temperature and improve boiler thermal efficiency.

※ This series gas fired water tube boiler is delivered as whole when leave factory, convenient for transportation, and has a short install period.

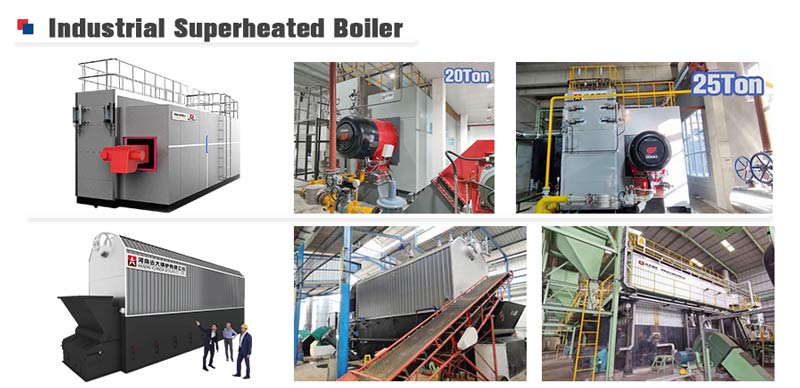

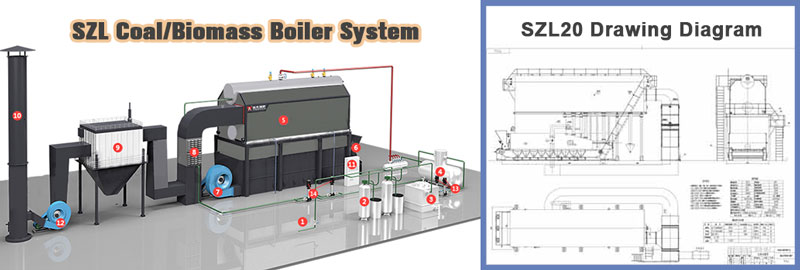

> Coal Biomass Type Superheated Boiler

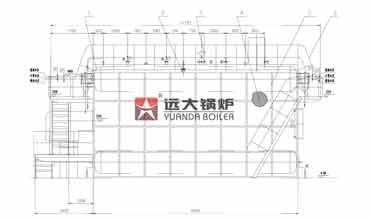

※ SZL/SZW series Water Tube Superheated Boiler, suitable for capacity demand in 2ton-50ton, 1.4mw-35mw.

※ Fuel: Coal, Charcoal, Wood biomass pellets, Woodchips, Palm kernel shells, Ricehusk, Peanut shells, Coconut Shells, etc.

※ It is double-drums water tube assembly chain grate boiler (A/D type). High technology, environmental and energy-saving. Large heating surface, make sure enough space for biomass burning, automatic fuel feeding and slag removing system.

Technical Design

Larger Comubustion furnace

Enough big combusition space, gas/oil burning sufficiently. Quick running, strong power to steam generating with 10minutes.

Membrane type water wall structure

Whole membrane type water wall structure is adopted around the furnace, has good sealing performance, low heat loss, no smoke and smoke leakage.

Higher quality steam generation

Compared with fire tube boiler, szs water tube boiler generating higher quality steam for using. (Moisture content<3%)

Saturated Steam & Superheated Steam

SZS series boiler can generate superheated steam for higher temperature compared with fire tube boiler, to reach different processing demand.Technical Parameter

| SZS Series Steam Boiler Technical Parameter | ||||||||

| Model | Rated capacity(t/h) | Rated pressure (Mpa) | Rated steam temperature(℃) | feed temperature(℃) | Thermal efficiency(%) | Fuel comsumption | max transportation weigh(t) | |

| light diesel oil(kg/h) | natural gas(Nm³/h) | |||||||

| SZS10-1.25/1.6/2.5/3.82-YQ | 10 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >98 | 618 | 660 | 36 |

| SZS15-1.25/1.6/2.5/3.82-YQ | 15 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >98 | 927 | 987 | 45 |

| SZS20-1.25/1.6/2.5/3.82-YQ | 20 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >98 | 1256 | 1316 | 52.6 |

| SZS25-1.25/1.6/2.5/3.82-YQ | 25 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >98 | 1545 | 1660 | 55.3 |

| SZS30-1.25/1.6/2.5/3.82-YQ | 30 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >98 | 1856 | 1981 | 63.7 |

| SZS40-1.25/1.6/2.5/3.82-YQ | 40 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >98 | 2470 | 2630 | 77.4 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | ||||||||

Boiler Accessories

About us

Yuanda Products

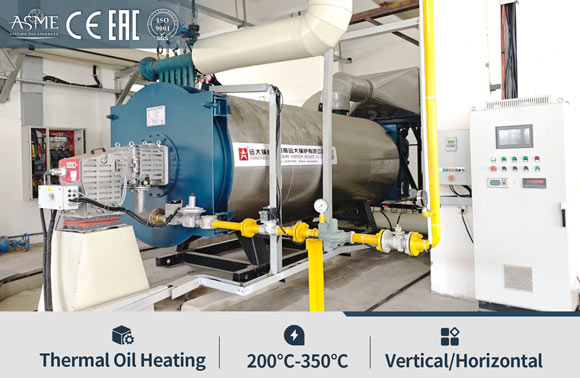

steam boiler, steam generator, hot water boiler, thermal oil heater boiler, hot air furnace, waste incinerator.

Various Structure

vertical, horizontal, fire tube boiler, water tube boiler, coils heater boiler, water membrane wall structure, sing drum, double drum...

Application

widely in all industries productions heating drying process, building central heating system, electricity generation.

About us

Yuanda Boiler Company established in 1956, qualified by ISO, CE, ASME, EAC, DOSH, and CRN, ensuring safety, reliability, and quality.

Yuanda Service

We provide tailored boiler solutions. Our team shares catalogues, evaluates your working conditions, and recommends the most suitable model for your needs.

✅ Design & Manufacture

Customized boiler design and system diagram. High-standard manufacturing with strict quality control, certified by ISO, CE, ASME, and more.

✅ Boiler Foundation Preparation

Complete foundation drawings, piping layout, and operation documents to ensure smooth installation and operation.

✅ Engineer Service

On-site guidance for installation and commissioning. Professional training for operators to ensure safe and efficient boiler operation.

✅ After-Sales Support

24/7 online technical assistance, spare parts supply, and regular maintenance services — ensuring long-term reliable performance.

Contact Yuanda

YUADNA PRODUCTS

HOT PRODUCTS

Send Inquiry

Capacity:

Capacity: Boiler Model:

Boiler Model: Fuel:

Fuel: Certificates:

Certificates: