Introduction

Yuanda Industrial Boiler is high-performance boiler system engineered for industrial and commercial use, featuring advanced combustion technology, high thermal efficiency, and low emissions.

Heating Medium : hot water, steam, thermal fluid

Heat Temperature: 50°C-400°C

Structure: vertical, horizontal

Combustion: diesel lpg gas hfo biogas hydrogen, electricity, coal wood biomass

> Fuel Oil Gas Fired Boiler

WNS Series Oil & Gas Fired Boiler is a horizontal three-pass fire tube boiler designed for high efficiency and stable performance.

1. High Thermal Efficiency --- Adopts horizontal three-pass fire tube structure with large heating surface and optimized combustion chamber, achieving thermal efficiency up to 98–99%.

2. Low Emissions --- Equipped with advanced low-NOx burners to ensure clean combustion and compliance with environmental standards.

3. Fully Automatic Operation --- Integrated PLC control system enables automatic ignition, load adjustment, safety interlock, and fault alarm for convenient and reliable operation.

4. Energy-Saving Design --- Large diameter corrugated furnace and threaded smoke tubes enhance heat transfer, reducing fuel consumption and operating costs.

5. Safe & Reliable --- Multiple safety protections including over-pressure, over-temperature, flame failure detection, and water level protection ensure stable long-term operation.

6. Compact & Easy Installation --- Skid-mounted or packaged structure allows quick installation and simple maintenance.

> Vertical Diesel Lpg Gas Boiler

Model: steam generator, steam boiler, hot water boiler

Structure: water tube once through design, fire tube two pass design

Vertical boiler occupies minimal floor space and reduces installation area. Compact and efficient, it provides reliable steam or hot water supply with easy installation and fast start-up.

> Electrical Boiler

Electric boiler uses electricity as the heat source to produce Hot Water/Steam by electric heating elements. Electrical energy is converted directly into heat and transferred to water inside the boiler.

No combustion, no flue gas, and no fuel storage, realizing clean operation and stable steam output, precise control and reliable safety protection.

Model: LDR series, WDR series

Structure: vertical, horizontal

Standard: normal, food-grade stainless steel

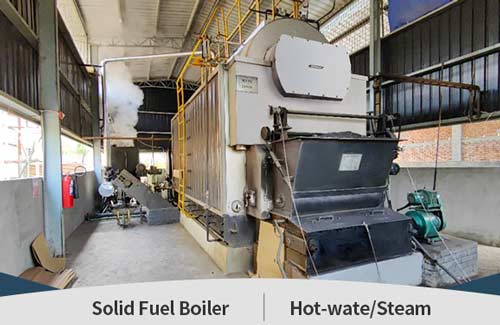

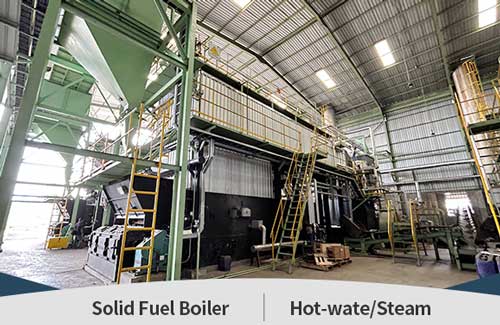

> Coal Biomass Fired Boiler

Feeding system: manual, automatic

Structure: fire tube, water tube

Type: vertical, horizontal

Combustion: wood biomass coal

LHS LSS Series Solid Fuel Boiler

Vertical coal biomass fired steam/hot water boiler, widely use in industrial heating system, small factory production heating drying, commercial laundry.

DZL DZW Series Automatic Coal Biomass Boiler

Automatic coal/biomass feeding system, high combustion efficiency for wood biomass. Optional chain gate, travelling grate, reciprocating grate stoker.

SZL Series Water Tube Boiler

Coal biomass fired water tube boiler with double drums. water membrane wall design boiler. larger combustion furnace. Combustion use chain grate or reciprocating grate stoker.

Technical Parameter

| Oil Gas Boiler Models | Rated capacity(t/h) | Rated pressure | Rated temperature(℃) | feed temperature(℃) | Thermal efficiency(%) | Exhaust temperation(℃) | Fuel comsumption | max transportation weigh(t) | |

| light diesel oil(kg/h) | natural gas(Nm³/h) | ||||||||

| WNS0.5 | 0.5 |

1bar-25ba 0.1mpa-2.5mpa |

100°C-350°C | 20/104 | >98 | 60-75 | 32.5 | 35.7 | 3.5 |

| WNS1 | 1 | 184/194/204 | >98 | 60-75 | 64.5 | 70.1 | 5.5 | ||

| WNS2 | 2 | 184/194/204 | >98 | 60-75 | 129.3 | 140.3 | 8 | ||

| WNS3 | 3 | 184/194/204 | >98 | 60-75 | 192.9 | 212.1 | 10.7 | ||

| WNS4 | 4 | 184/194/204 | >98 | 60-75 | 258.2 | 283.4 | 11.6 | ||

| WNS6 | 6 | 184/194/204 | >98 | 60-75 | 388.6 | 424.2 | 17.5 | ||

| WNS8 | 8 | 184/194/204/226 | >98 | 60-75 | 514.6 | 566.3 | 22.5 | ||

| WNS10 | 10 | 184/194/204/226 | >98 | 60-75 | 641.7 | 707.8 | 26.8 | ||

| WNS15 | 15 | 184/194/204/226 | >98 | 60-75 | 960.1 | 1061.7 | 35.2 | ||

| WNS20 | 20 | 184/194/204/226 | >98 | 60-75 | 1276.2 | 1415.8 | 45.5 | ||

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||

Boiler Accessories

About us

Yuanda Products

steam boiler, steam generator, hot water boiler, thermal oil heater boiler, hot air furnace, waste incinerator.

Various Structure

vertical, horizontal, fire tube boiler, water tube boiler, coils heater boiler, water membrane wall structure, sing drum, double drum...

Application

widely in all industries productions heating drying process, building central heating system, electricity generation.

About us

Yuanda Boiler Company established in 1956, qualified by ISO, CE, ASME, EAC, DOSH, and CRN, ensuring safety, reliability, and quality.

One Stop Solution

We provide more than just a boiler — we deliver a complete and integrated heating system solution tailored to your industry.

From initial consultation to long-term technical support, our team ensures your boiler system operates safely, efficiently, and reliably.

✅ System Design & Engineering Support

Heat load calculation

Boiler model selection

Fuel analysis & recommendation

System layout design

Energy efficiency optimization

Our engineers customize every solution based on your production requirements and site conditions.

✅ Complete Boiler System Supply

Boiler unit (steam / hot water / thermal oil)

Combustion system

Pumps and water treatment system

Control cabinet (PLC optional)

Valves, pipelines & accessories

Safety protection devices

All components are professionally matched to ensure stable performance and long service life.

✅Pre-Installation & Factory Testing

Main components are assembled and tested before shipment, reducing installation time and minimizing on-site risks.

✅ Installation & Commissioning Support

Installation guidance

On-site or remote commissioning

Operator training

Performance testing

We make sure your system starts up smoothly and reaches optimal working conditions.

✅ After-Sales Service & Spare Parts

24/7 technical support

Spare parts supply

Maintenance guidance

Long-term operation assistance

We focus on building long-term partnerships with our clients worldwide.

Contact Yuanda

YUADNA PRODUCTS

Send Inquiry

Capacity:

Capacity: Pressure:

Pressure: Power:

Power: Temperature:

Temperature: