Introduction

> Exhaust Gas Boiler

Exhaust Gas Boiler is a high-efficiency energy recovery system designed to utilize waste heat from diesel engines, gas engines, or other industrial exhaust sources to produce steam.

It can generate saturated steam or hot water without additional fuel consumption, helping customers reduce operational costs and improve energy efficiency.

Exhaust Gas Boiler Advantages

✅ Energy Saving – Utilizes waste exhaust heat to produce steam, no extra fuel required.

✅ High Efficiency – Optimized heat exchange tubes and flue gas flow design ensure maximum heat recovery.

✅ Environmental Protection – Reduces CO₂ emissions and overall carbon footprint.

✅ Compact Structure – Easy to install, minimal space required, suitable for retrofit projects.

✅ Reliable Operation – Fully automatic control system with multiple safety protections.

✅ Flexible Design – Customizable pressure, temperature, and configuration to match engine type and site conditions.

Technical Parameter

| Waste Heat Recovery Boiler design | ||

| please provide the parameters listed in the table below | ||

| Part One | Industry | |

| Part Two | Flue gas side parameters | unit |

| 1 | Flue gas side pressure of boiler inlet | Pa |

| 2 | Range of boiler inlet flue gas volume (standard condition) | N m3/h |

| 3 | Design value of boiler inlet flue gas (standard condition) | Nm3/ h |

| 4 | Temperature range of boiler inlet flue gas | °C |

| 5 | Design value of boiler inlet flue gas temperature | °C |

| 6 | Boiler outlet flue gas temperature | ~℃ |

| Part Three | Boiler side parameters | |

| 1 | Rated steam capacity of the boiler (if any) | t/h |

| 2 | Rated steam pressure of boiler | MPa |

| 3 | Boiler rated steam temperature | °C |

| 4 | Boiler feed water temperature | °C |

| Part Four | Other required parameters | |

| 1 | Elevation and size of smoke outlet of industrial furnace | m |

| 2 | Estimated smoke outlet elevation of waste heat boiler | m |

| 3 | Estimated land requirement for waste heat boiler (length m×width m×height m) | m |

| 4 | Does the waste heat boiler need the supplier to support the top rain shed? | |

| 5 | Boiler layout (vertical or horizontal layout) | |

| Part Five | Auxiliary machine | |

Supply Boiler & Accessories

About us

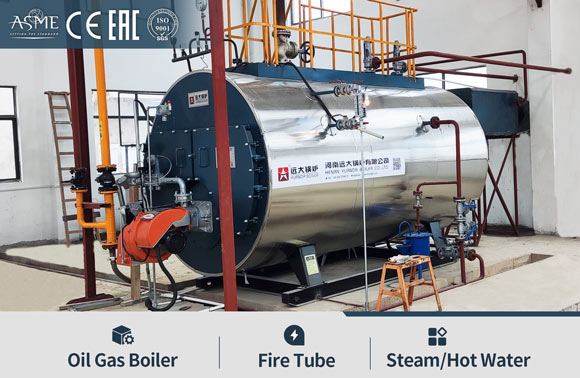

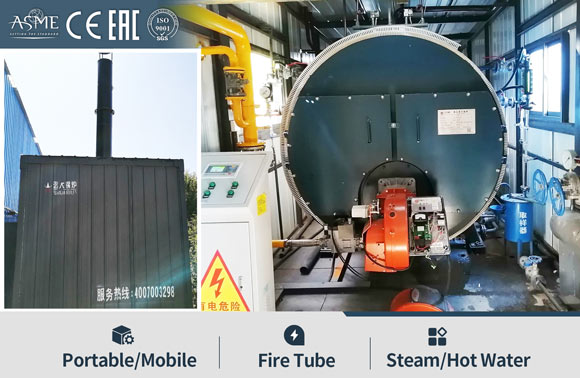

Yuanda Products

steam boiler, steam generator, hot water boiler, thermal oil heater boiler, hot air furnace, waste incinerator.

Various Structure

vertical, horizontal, fire tube boiler, water tube boiler, coils heater boiler, water membrane wall structure, sing drum, double drum...

Application

widely in all industries productions heating drying process, building central heating system, electricity generation.

About us

Yuanda Boiler Company established in 1956, qualified by ISO, CE, ASME, EAC, DOSH, and CRN, ensuring safety, reliability, and quality.

Yuanda Service

We provide tailored boiler solutions. Our team shares catalogues, evaluates your working conditions, and recommends the most suitable model for your needs.

✅ Design & Manufacture

Customized boiler design and system diagram. High-standard manufacturing with strict quality control, certified by ISO, CE, ASME, and more.

✅ Boiler Foundation Preparation

Complete foundation drawings, piping layout, and operation documents to ensure smooth installation and operation.

✅ Engineer Service

On-site guidance for installation and commissioning. Professional training for operators to ensure safe and efficient boiler operation.

✅ After-Sales Support

24/7 online technical assistance, spare parts supply, and regular maintenance services — ensuring long-term reliable performance.

Contact Yuanda

YUADNA PRODUCTS

HOT PRODUCTS

Send Inquiry

Types:

Types: Capacity:

Capacity: Heat Source:

Heat Source: Structure:

Structure: