Introduction

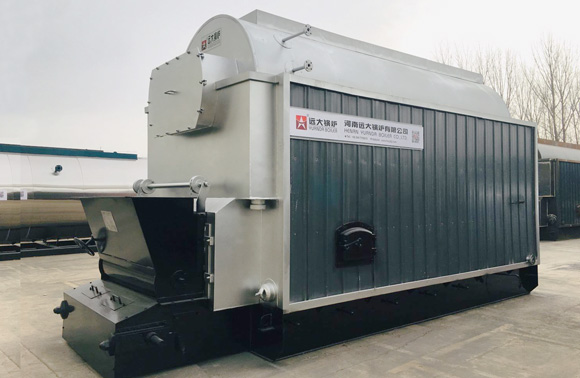

YDHT series Hot Air Generator Furnace

(Use biomass, wood, solid waste, husk, palm shells, palm fibre, bagasse, coconuts, sawdust, ect)

1. In a biomass hot air stove furnace, the biomass fuel is burned to produce heat. This heat is then transferred to the surrounding air, creating hot air.

2. It is widely used in industries such as grain, fertilizer, chemical, printing and dyeing, vegetable dehydration, residue drying and mine heating.

3. Biomass hot air stove furnaces have gained popularity as a renewable and environmentally friendly alternative to traditional fossil fuel-based heating systems. They can be used for residential, commercial, and industrial applications, providing efficient heating while reducing greenhouse gas emissions and dependence on non-renewable energy sources.

Design Advantages

1. Flexibility of various fuels: The reciprocating grate can perfectly burn various fuels, such as coal, wood, potato chips with low calorific value and high ash content, bark, sawdust, forest waste, agricultural waste, rice husk, etc.

2. Suitable for fuels with high moisture content: the grate can be divided into four zones:

(1). Drying zone: Preheat and disperse fuel

(2). Gasification zone: the surface of gasified fuel for easy combustion

(3). Combustion zone: complete combustion of fuel

(4). Burnout zone: Ash removal and collection

3. Perfect and Complete Combustion: The reciprocating motion can make the fuel disperse and turn over perfectly during the combustion process, so the combustion is perfect and complete.

4. Good insulation and high thermal efficiency: The thermal insulation layer is 600mm, less heat loss and complete combustion can guarantee 90% thermal efficiency.

5. Long life: The combustion chamber frame is made of high-strength steel and lined with cast heat-resistant cement and refractory bricks. The grate bars are made of heat-resistant alloy steel. Normal life expectancy is 10 years.

6. Automatic operation: Fuel feeding, ash discharge and grate movement are fully automatic.

7. Stable output temperature: Temperature control is achieved by precisely adjusting combustion air, grate movement and feeding speed. The grate drive motor is of the stepless speed regulation type.

8. Safety measures: Equipped with exhaust fans to generate negative pressure combustion conditions. The ash removal port is water-sealed. Negative pressure and sealed combustion chamber ensure safe operation and cooling of the grate.

> How to Choose A Suitable Boiler

1. Basic Boiler Information For Your Project

Fuel options: Gas Lpg Diesel Heavy-oil Biogas Dual-fuel, Electricity, Coal, Charcoal, Wood, Biomass, Pellets, EFB Palm-kernel-shells, Rice-husk, Peanut-shells, Cashew-nuts-shells, Sunflower-seeds-shells, Bagasse, etc.

Thermal capacities options: 100kg-50000kg, 70kw-35000kw, 5hp/bhp-3000hp/bhp, (million-btu, pounds/lbs, liters,etc)

Heat medium options: saturated/superheated steam, hot water, thermal oil.

Structure options: Fire tube boiler, water tube boiler, water-tube fire-tube boiler

Layout options: Vertical boiler, Horizontal boiler.

Operating-mode options: Automatic, manual

Note: please feel free to send all requirements, we could help you better.

2. Calculating Running Cost

Specific consumption analysis report

Different types boiler running consumption comparison analysis report

(Note: Report is based on your local energy source price)

3. Boiler Accessories (essential or optional)

Control panel, Water treatment device, Economizer, Conderser, Heat recovery unit, Deaerator, Solid fuel burning combustions stoker (chain-grate, reciprocating-grate, travelling-grate, fixed-grate), Steam header, Pumps, Water level gauge/sensor, Pressure guage/sensor, Safety valves, etc.

Note: Any special request, please send all details.

Our Supply Equipment List

Furnace Advantages

Unique warehouse and auto feeding

The big speed bin design could control fuel transmit mass automatically according to the thermal energy, isolate flame and flue to prevent tempering

Whole membrane water wall

Increased 50% heating area than traditional, refractory brick furnace wall will reduce weight and transport cost, improve efficiency and energy saving

Security guaranteed & Automation

With a set of alarm,protection and security guaranteed, 100% safety. Control cabinet use siemens elements, trustable quality & control strictly

Economizer & Dust collector device

Reuse waste heat in exhaust gas, energy saving devide (economizer); Remove the dust and ash, protect envrionment and reduce pollutionFAQ of SZL Biomass Boiler

Question: what's thermal efficiency of SZL biomass boiler?

Answer: SZL biomass boiler has higher efficiency than other old design boiler, take 10ton palm shells boiler example, thermal efficiency>86.2%

Question: Are there other biomass boiler models ?

Answer: Yes, including dzl chain grate biomass boiler, dzh biomass boiler, vertical biomass boiler, chain grate boiler, reciprocating grate boiler...

Question: Do you support customized boiler service for projects?

Answer: Yes, we have technique research center team, make unique boiler solution. Tell about your requirements, let's have more discuss.

Question: Do you supply complete accessories for boiler system?

Answer: Yes, we supply all accessories such water treatment device, economizer, ID fan, forced fan, slag remover, sawdust collector...

Question: Do you supply installation services ?

Answer: Our senior engineer Mr.Gao already arrived 50+countries for boiler services. Now, we adapt online video guidance for quick services.

PRODUCT LIST

YOU MAY ALSO LIKE

Ask For Catalogue

Send Inquiry

Product capacity:

Product capacity: Working pressure:

Working pressure: Available fuel:

Available fuel: Available industries:

Available industries: