Introduction

Vertical Waste Cloth/Jute Boiler

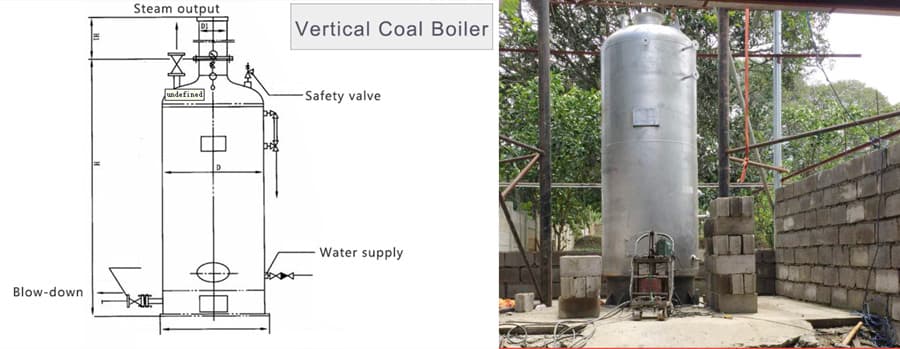

1. 200kg-2000kg vertical type boiler, adopt fire tube/water tube structure, coal/wood/biomass fuel/waste colth burning boiler. Heating capacity in 100kw-1400kw or 200kg-2000kg.

2. Vertical manual feeding jute/jhute boiler, the boiler body mainly made of U-circle, boiler drum, shell cover, furnace, horizontal water tube, vertical tube, convection tubes, pressure parts. Set manhole on shell cover, convenient for boiler maintenance and clean.

Technical Parameter

| Vertical Jute Boiler Technical Parameter Table | |||||||

| Model | Rated evaporation(T/H) | Rated pressure (Mpa) | Saturation temperature(℃) | Thermal efficiency(%) | Water capacity(L) | Fuel consumption(Kg/H) | power supply(V) |

| LSC0.08-0.7 | 0.08 | 0.7 | 170 | ≥90 | 29.5 | 12 | 220 |

| LSC0.12-0.7 | 0.12 | 0.7 | 170 | ≥90 | 29.5 | 17 | 220 |

| LSC0.16-0.7 | 0.16 | 0.7 | 170 | ≥90 | 29.5 | 25 | 220 |

| LSC0.23-0.7 | 0.23 | 0.7 | 170 | ≥90 | 29.5 | 33 | 220 |

| LSC0.30-0.7 | 0.3 | 0.7 | 170 | ≥90 | 47.5 | 50 | 220 |

| LSC0.50-0.7 | 0.5 | 0.7 | 170 | ≥90 | 29.5 | 75 | 220 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||

Product Features

Corrugated Furnace

Big size corrugated furnace,Increasing the heat surface area, and satisfying free expansion of furnace pipes when heating.

Spirally corrugated fire tube

Strengthening heat transfer, eliminating welding stress, enhance heat transfer bility, flue gas flow in tube, said fire tubes.

Three pass wet back type

Extend the flue gas process, enhance heat transfer, Lower the temperature of the rear tube to prevent cracking

Aluminum silicate insulation

Double layer 12cm aluminum silicate insulation. Sealed tightly to avoid air leaks.Boiler Structure

Higher efficiency & Energy-saving

Optimized design CAD furnace/corrugated tubes/wing shape flue/new arch design, enhancing heat transfer efficiency. Equipped with energy saving device such as economizer to absorb heat of exhaust gas, economic & eco-friendly.

Automatic feeding coal boiler

Automatic chain belt grate, easier operation, avoid the problem of air leakage/fuel leakage/uneven ventilation. Double-sided air inlet chamber can flexibly adjust the air volume and distribute the air uniformly to ensure full combustion.

High Quality & Strong Power

Design steam-water separator, reduce steam humidity and ensure steam quality. Boiler design 5-10% overload capacity, satisfy customers' demand for factory using. Enough steam output per hour.

Safety & 25+Years Lifespan

We already manufacturing boiler for 60+Years, mature skilled technician team, advanced production processes, strict quality inspection control, CE & ISO certified quality, global service for boiler install & commissioning & training operator.

PRODUCT LIST

YOU MAY ALSO LIKE

Ask For Catalogue

Send Inquiry

Product Brand:

Product Brand: Product Model:

Product Model: Available Fuel:

Available Fuel: Available Industries:

Available Industries: